DCC1002 User Guide: Difference between revisions

No edit summary |

|||

| Line 28: | Line 28: | ||

{{UGC-Start}} | {{UGC-Start}} | ||

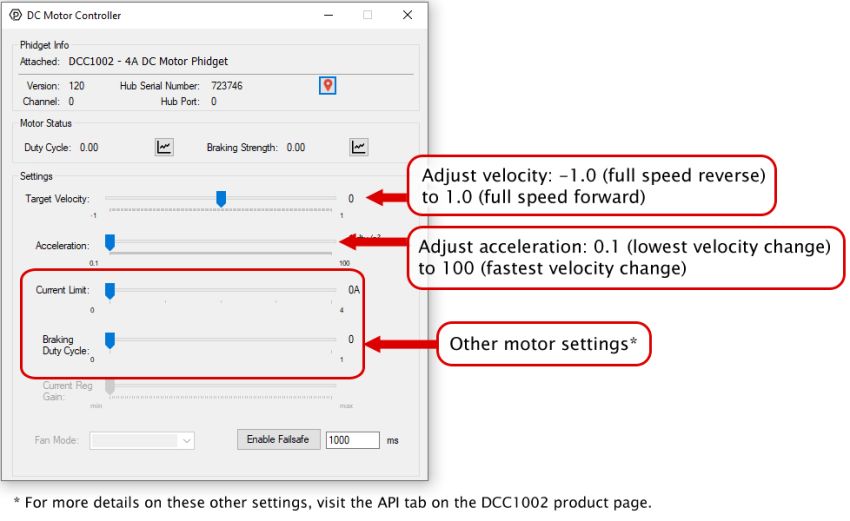

{{UGC-Entry|DC Motor:| Controls the velocity and current of the motor| | {{UGC-Entry|DC Motor Controller:| Controls the velocity and current of the motor| | ||

In your Control Panel, double click on "DC Motor Controller": | In your Control Panel, double click on "DC Motor Controller": | ||

[[Image:DCC1002-DCMotor.jpg|center|850px|link=]]}} | [[Image:DCC1002-DCMotor.jpg|center|850px|link=]]}} | ||

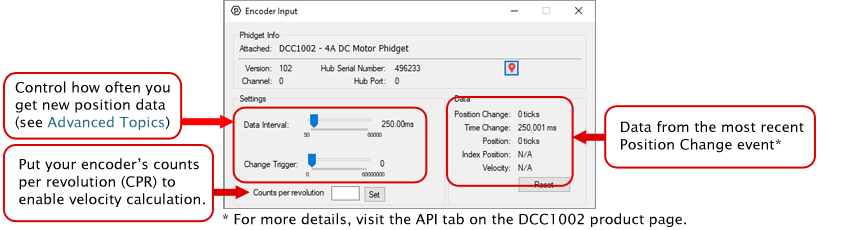

{{UGC-Entry|Encoder:| Reads encoder input so you can implement closed-loop control of the motor | {{UGC-Entry|Encoder Input:| Reads encoder input so you can implement closed-loop control of the motor | ||

| | | | ||

In your Control Panel, double click on "Encoder Input": | In your Control Panel, double click on "Encoder Input": | ||

Revision as of 17:13, 17 March 2021

Part 1: Setup

Part 2: Using Your Phidget

About

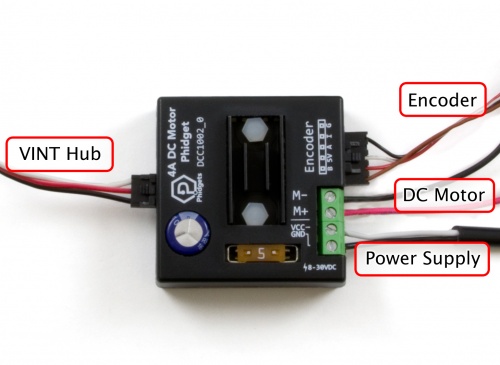

Control a brushed DC motor with a current rating of up to 4A with the DCC1002. With this Phidget, you can:

- Set the velocity (forward or reverse) and acceleration of your motor with the DC Motor Controller

- Set a specific target position with the Motor Position Controller (requires an encoder)

Explore Your Phidget Channels Using The Control Panel

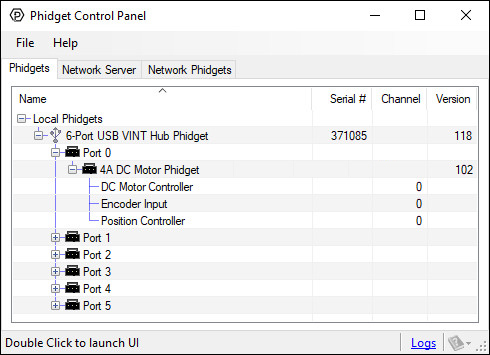

You can use your Control Panel to explore your Phidget's channels.

1. Open your Control Panel, and you will find the following channels:

2. Double click on a channel to open an example program. Each channel belongs to a different channel class:

In your Control Panel, double click on "DC Motor Controller":

In your Control Panel, double click on "Encoder Input":

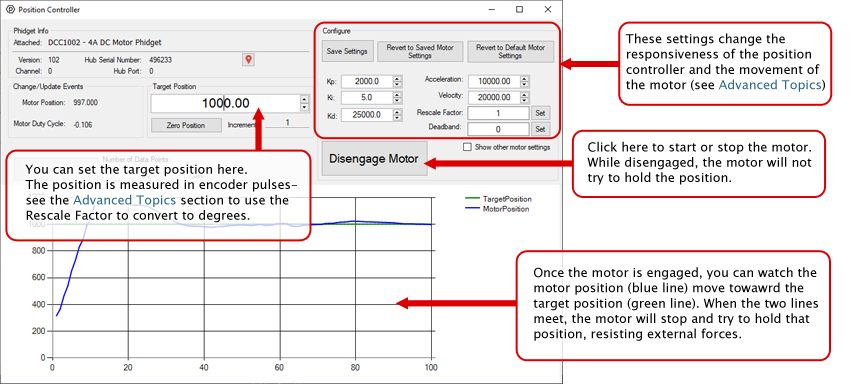

In your Control Panel, double click on "Position Controller":

Part 3: Create your Program

Part 4: Advanced Topics and Troubleshooting

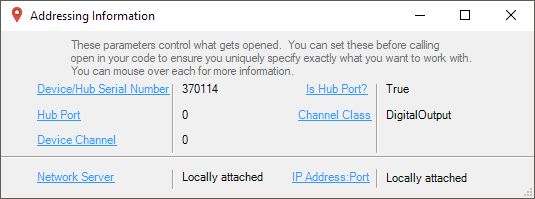

Before you open a Phidget channel in your program, you can set these properties to specify which channel to open. You can find this information through the Control Panel.

1. Open the Control Panel and double-click on the red map pin icon:

2. The Addressing Information window will open. Here you will find all the information you need to address your Phidget in your program.

See the Phidget22 API for your language to determine exact syntax for each property.

The Change Trigger is the minimum change in the sensor data needed to trigger a new data event.

The Data Interval is the time (in ms) between data events sent out from your Phidget.

The Data Rate is the reciprocal of Data Interval (measured in Hz), and setting it will set the reciprocal value for Data Interval and vice-versa.

You can modify one or both of these values to achieve different data outputs. You can learn more about these properties here.

There are a number of settings that can be adjusted to customize the position controller. You can save these variables into the program so you don't have to re-enter them manually (NOTE: This does not store the settings on the DCC1002, it simply saves them inside the control panel program, so you'll have to re-enter them if it's used on another computer).

Kp, Ki, and Kd

You can set the control parameters Kp, Ki, and Kd in order to change the behavior of the control loop. For more information on how each of these three tuning parameters affect the control loop, see “Control Loop Parameters ”.

Velocity and Acceleration

Velocity is how fast the motor will move to the target position, and acceleration controls how quickly the motor will reach its velocity and how quickly it will slow down. These values are measured in position per second and position per second squared, and position by default is measured in encoder pulses.

Rescale Factor

If you want position to be measured in another unit (degrees, for example), you can set the rescale factor. For more information on choosing the correct rescale factor, see “Setting the Rescale Factor”.

Deadband

Sometimes the motor will oscillate back and forth across the target position when holding position. Adding a deadband will widen the target position so the motor will stop when it gets within the target position plus or minus the deadband.

Current Limit

Setting the current limit gives you control over how much power is being supplied to the motor. Generally, we advise that you set the current limit to your motor’s specified coil current.

Fan Mode

This turns the cooling fan on and off. Setting it to auto will result in the fan turning on only when the temperature sensor detects rising board temperatures.

Encoder IO Mode

Changes between different encoder modes based on your encoder’s circuitry. For more information see the Encoder Primer.

Current Regulator Gain

Depending on power supply voltage and motor coil inductance, the current through the motor can change relatively slowly or extremely rapidly. A physically larger DC Motor will typically have a lower inductance, requiring a higher current regulator gain. A higher power supply voltage will result in motor current changing more rapidly, requiring a higher current regulator gain. If the current regulator gain is too small, spikes in current will occur, causing large variations in torque, and possibly damaging the motor controller. If the current regulator gain is too high, the current will jitter, causing the motor to sound 'rough', especially when changing directions.

In order to get the desired behavior from your controller, you will have to tune your control parameters. This video explains the tuning procedure and gives information on how the controller works.

The DCC1002 can connect to any of the encoders we sell without any modification just by setting the EncoderIOMode property to Push-Pull . If you're trying to use your own encoder, you may need to change the IO mode to Open Collector or Line Driver mode. Have a look at the Encoder Primer for more details on what to use.

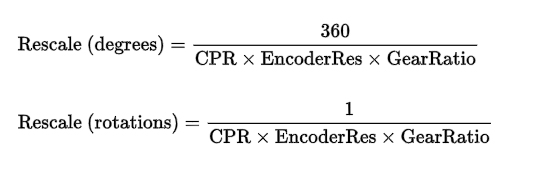

There are three pieces of information to consider when setting a rescale factor to change your units into degrees or rotations:

- Your encoder's CPR (counts per rotation)

- Your encoder interface's resolution

- Your motor's gear ratio

First, check your encoder's datasheet for the CPR. It's usually 360 or 300. This is the number of quadrature cycles the encoder will send out for one full rotation.

Next, you need your encoder interface's resolution. The encoder port on the DCC1002 has a x4 resolution, meaning it reads in 4 pulses per quadrature cycle (see the Encoder Primer for a more in-depth explanation).

Next, you need to find out the gear ratio in your motor's datasheet. Note: If you plan on having your motor run for many rotations in a row, try to find the exact gear ratio, expressed as a fraction. Using the rounded value will result in accumulating errors the more you rotate.

Once you have these numbers, you can calculate the rescale factor:

For example, if you wanted to have your motor's position measured in degrees and your encoder had 300 CPR and your motor had a 50 801⁄895 : 1 gearbox, you would set your rescale factor to 360 / 300*4*(50+(801/895)), or 0.005894.

Reverse your motor’s wires. The control loop has to make an assumption about what direction your motor moves with a positive voltage, and in this case, the assumption was incorrect. Don’t worry, DC motors are fine being wired up backward since they’re essentially just a long loop of wire on the inside.