PRE1000 User Guide

Part 1: Setup

Welcome to the PRE1000 user guide! In order to get started, make sure you have the following hardware on hand:

- PRE1000 - Barometer Phidget

- VINT Hub

- Phidget cable

- USB cable and computer

Next, you will need to connect the pieces:

- Connect the PRE1000 to the VINT Hub using the Phidget cable.

- Connect the VINT Hub to your computer with a USB cable.

Now that you have everything together, let's start using the PRE1000!

Phidget Control Panel

In order to demonstrate the functionality of the PRE1000, the Phidget Control Panel running on a Windows machine will be used.

The Phidget Control Panel is available for use on both macOS and Windows machines.

Windows

To open the Phidget Control Panel on Windows, find the ![]() icon in the taskbar. If it is not there, open up the start menu and search for Phidget Control Panel

icon in the taskbar. If it is not there, open up the start menu and search for Phidget Control Panel

macOS

To open the Phidget Control Panel on macOS, open Finder and navigate to the Phidget Control Panel in the Applications list. Double click on the ![]() icon to bring up the Phidget Control Panel.

icon to bring up the Phidget Control Panel.

For more information, take a look at the getting started guide for your operating system:

Linux users can follow the getting started with Linux guide and continue reading here for more information about the PRE1000.

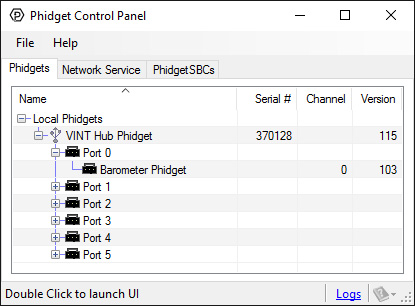

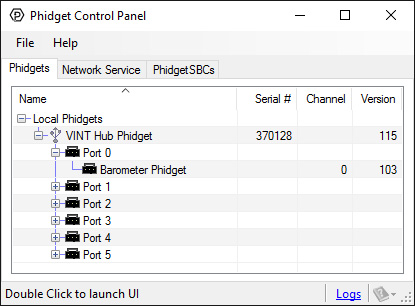

First Look

After plugging the PRE1000 into your computer and opening the Phidget Control Panel, you will see something like this:

The Phidget Control Panel will list all connected Phidgets and associated objects, as well as the following information:

- Serial number: allows you to differentiate between similar Phidgets.

- Channel: allows you to differentiate between similar objects on a Phidget.

- Version number: corresponds to the firmware version your Phidget is running. If your Phidget is listed in red, your firmware is out of date. Update the firmware by double-clicking the entry.

The Phidget Control Panel can also be used to test your device. Double-clicking on an object will open an example.

Part 2: Using Your Phidget

About

The Barometer Phidget measures absolute pressures within the range of 50kPa and 110kPa at a resolution of 250 mPa. If you read air pressures outside this range, an error event will trigger.

Explore Your Phidget Channels Using The Control Panel

You can use your Control Panel to explore your Phidget's channels.

1. Open your Control Panel, and you will find the following channel:

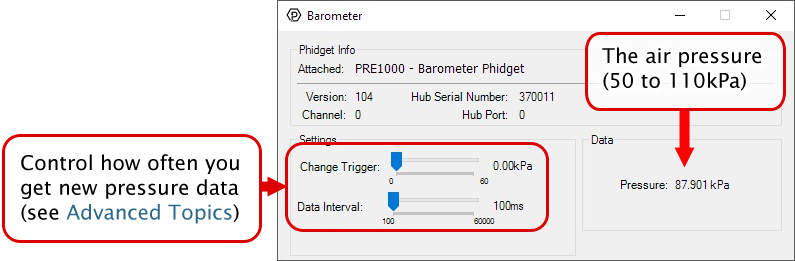

2. Double click on the channel to open the example program. This channel belongs to the PressureSensor channel class:

In your Control Panel, double click on "Barometer Phidget":

Part 3: Create your Program

Part 4: Advanced Topics and Troubleshooting

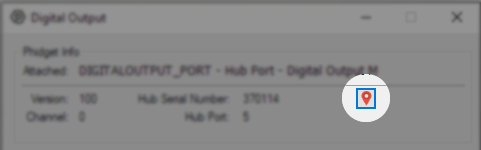

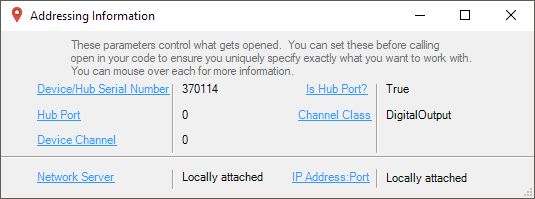

Before you open a Phidget channel in your program, you can set these properties to specify which channel to open. You can find this information through the Control Panel.

1. Open the Control Panel and double-click on the red map pin icon:

2. The Addressing Information window will open. Here you will find all the information you need to address your Phidget in your program.

See the Phidget22 API for your language to determine exact syntax for each property.

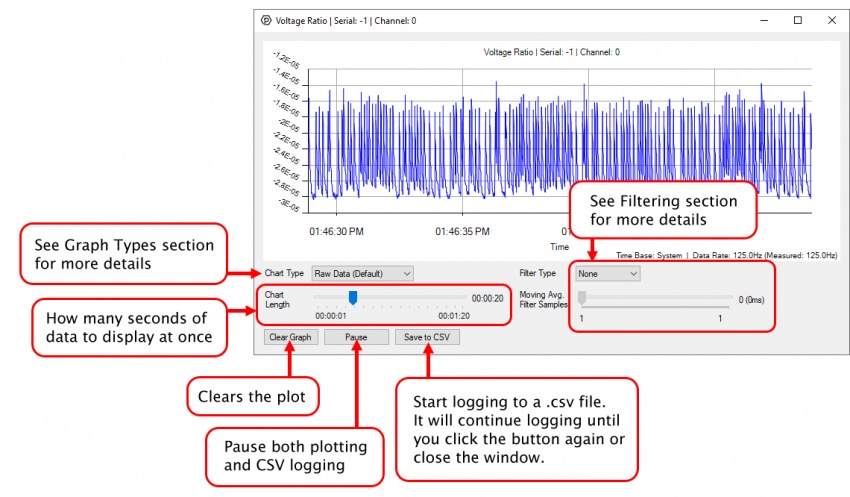

Note: Graphing and logging is currently only supported in the Windows version of the Phidget Control Panel.

In the Phidget Control Panel, open the channel for your device and click on the ![]() icon next to the data type that you want to plot. This will open up a new window:

icon next to the data type that you want to plot. This will open up a new window:

If you need more complex functionality such as logging multiple sensors to the same sheet or performing calculations on the data, you'll need to write your own program. Generally this will involve addressing the correct channel, opening it, and then creating an Event Handler and adding graphing/logging code to it.

The quickest way to get started is to download some sample code for your desired programming language and then search google for logging or plotting in that language (e.g. "how to log to csv in python") and add the code to the existing change handler.

Filtering

You can perform filtering on the raw data in order to reduce noise in your graph. For more information, see the Control Panel Graphing page.

Graph Type

You can perform a transform on the incoming data to get different graph types that may provide insights into your sensor data. For more information on how to use these graph types, see the Control Panel Graphing page.

The Change Trigger is the minimum change in the sensor data needed to trigger a new data event.

The Data Interval is the time (in ms) between data events sent out from your Phidget.

The Data Rate is the reciprocal of Data Interval (measured in Hz), and setting it will set the reciprocal value for Data Interval and vice-versa.

You can modify one or both of these values to achieve different data outputs. You can learn more about these properties here.

The PRE1000 reports the absolute pressure of its surroundings; in other words, the pressure compared to a perfect vacuum. If you plan on using this sensor as a barometer, you need to convert to barometric pressure. You can use conversion calculators such as this above sea level barometer reading correction calculator to make the adjustment based on your location's elevation.

Since the PRE1000 makes absolute pressure measurements, you could use it with a temperature sensor to measure changes in altitude, as long as you know your pressure and height to begin with. The following is the barometric formula:

where

- is the pressure at height

- is the pressure at height zero

- is the molar mass of earth's air (0.0289644 kg/mol)

- is the gravitational constant (9.80665 m/s^2)

- is the current height

- is the universal gas constant (8.3144598 J/(mol*K))

- is the standard temperature in degrees Kelvin.

This formula can be rearranged for as follows:

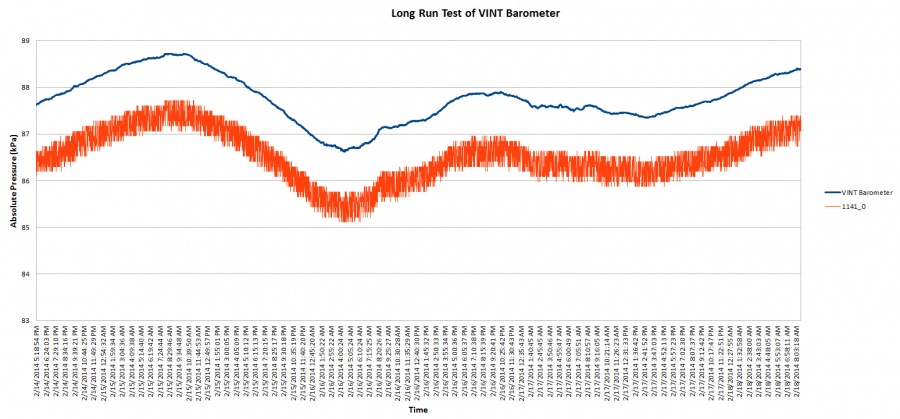

A long-run test was performed to compare the accuracy of the PRE1000 with that of the 1141 - Absolute Gas Pressure Sensor. For 87 hours, both sensors measured the absolute air pressure indoors in the same room, with the same change sensitivity.

As you can see, the PRE1000 is significantly less noisy. The average difference between any two successive samples for the 1141 is 237.17Pa, while for the PRE1000, it is 3.19Pa. Both sensors consistently differ by an average of 1.23kPa, but this error could be easily calibrated out due to the consistency of the offset.