Load Cell Guide

Introduction

A load cell is a force sensing module - a carefully designed metal structure, with small elements called strain gauges mounted in precise locations on the structure. Load cells are designed to measure a specific force, and ignore other forces being applied. The electrical signal output by the load cell is very small and requires specialized amplification. Fortunately, the DAQ1500 - Wheatstone Bridge Phidget will perform all the amplification and measurement of the electrical output.

Some load cells are designed to measure force in one direction on one axis (e.g. down, but not up), while others are more versatile. Be sure to keep this in mind when selecting a load cell for your application.

How they work

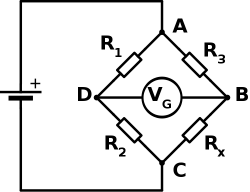

Strain-gauge load cells convert the load acting on them into electrical signals. The measuring is done with very small resistor patterns called strain gauges - effectively small, flexible circuit boards. The gauges are bonded onto a beam or structural member that deforms when weight is applied, in turn deforming the strain-gauge. As the strain gauge is deformed, it’s electrical resistance changes in proportion to the load.

The main result is that when measured by a DAQ1500 - Wheatstone Bridge Phidget, they produce a signal that is directly proportional to the force applied, once a baseline offset (zero, tare) is accounted for.

Common Load Cell Types

Single-Point Load Cells

This Single Point Load Cell is used in small jewelry scales and kitchen scales. It’s mounted by bolting down the end of the load cell where the wires are attached, and applying force on the other end in the direction of the arrow. This type of load cell is designed such that the effect of the specific placement of the force is minimized. If you mount a small platform on the load cell, as would be done in a small scale, this load cell provides consistent readings regardless of the position of the load on the platform.

Button Load Cells

This Button Load Cell is used in applications that require a thin form factor. The bottom of the load cell is bolted to a surface, and force is applied to the button on the top. By loading only the button, which is slightly rounded, the load cell is less sensitive to errors resulting from the load not being perfectly aligned with the middle of the load cell.

S-Type Load Cells

This S-Type load cell can be operated in compression or tension, as illustrated below.

Calibration

Load cells have enough variation through manufacturing differences that we strongly recommend each one be calibrated once it is built into its final application. Thankfully this is a fairly easy process, and you can find instructions and an example of this on our page for Calibrating Load Cells.

Multiple Load Cells Measuring the Same Platform

Some applications (such as bathroom scales) use multiple load cells in concert to get a better reading of a weight on a platform, regardless of positioning. In these applications, it is possible to connect all the load cells together in parallel on a single channel of a DAQ1500 - Wheatstone Bridge Phidget, and calibrate the entire system at once. However, we only recommend this type of solution in applications that can be quickly re-zeroed (tared) like the previously mentioned bathroom scale. For all other applications, we recommend measuring and calibrating each load cell individually.

Load Cell Specification Glossary

When comparing load cells, there are a number of specifications to consider. This section lists and defines the properties commonly listed on load cells.

Capacity

The maximum load the load cell is designed to measure within its specifications.

Creep

The change in sensor output occurring over 30 minutes, while under load at or near capacity and with all environmental conditions and other variables remaining constant.

Full Scale or FS

Used to qualify error - FULL SCALE is the change in output when the sensor is fully loaded. If a particular error (for example, Non-Linearity) is expressed as 0.1% F.S., and the sensor's maximum range is 0.1V/V, the maximum non-linearity that will be seen over the operating range of the sensor will be 0.0001V/V. An important distinction is that this error doesn’t have to only occur at the maximum load. If you are operating the sensor at a maximum of 10% of capacity, for this example, the non-linearity would still be 0.0001V/V, or 1% of the operating range that you are actually using.

Hysteresis

If a force equal to 50% of capacity is applied to a load cell which has been at no load, a given output will be measured. The same load cell is at full capacity, and some of the force is removed, resulting in the load cell operating at 50% capacity. The difference in output between the two test scenarios is called hysteresis.

Excitation Voltage

Specifies the voltage that can be applied to the power/ground terminals on the load cell. In practice, if you are using the load cell with a Phidget, you don’t have to worry about this spec.

Input Impedance

Determines the power that will be consumed by the load cell. The lower this number is, the more current will be required, and the more heating will occur when the load cell is powered. In very noisy environments, a lower input impedance will reduce the effect of Electromagnetic interference on long wires between the load cell and Phidget.

Insulation Resistance

The electrical resistance measured between the metal structure of the load cell, and the wiring. The practical result of this is the metal structure of the load cells should not be energized with a voltage, particularly higher voltages, as it can arc into the Phidget. Commonly the load cell and the metal framework it is part of will be grounded to earth or to your system ground.

Maximum Overload

The maximum load which can be applied without producing a structural failure.

Non-Linearity

Ideally, the output of the sensor will be perfectly linear, and a simple 2-point calibration will exactly describe the behaviour of the sensor at other loads. In practice, the sensor is not perfect, and Non-linearity describes the maximum deviation from the linear curve. Theoretically, if a more complex calibration is used, some of the non-linearity can be calibrated out, but this will require a very high accuracy calibration with multiple points.

Non-Repeatability

The maximum difference the sensor will report when exactly the same weight is applied, at the same temperature, over multiple test runs.

Operating Temperature

The extremes of ambient temperature within which the load cell will operate without permanent adverse change to any of its performance characteristics.

Output Impedance

Roughly corresponds to the input impedance. If the Output Impedance is very high, measuring the bridge will distort the results. The Phidget carefully buffers the signals coming from the load cell, so in practice this is not a concern.

Rated Output

Is the difference in the output of the sensor between when it is fully loaded to its rated capacity, and when it’s unloaded. Effectively, it’s how sensitive the sensor is, and corresponds to the gain calculated when calibrating the sensor. More expensive sensors have an exact rated output based on an individual calibration done at the factory.

Resolution

Resolution is somewhat misleading when it comes to load cells. People often ask why we don't specify the resolution for our load cells. The fact of the matter is, resolution isn't really a property of the load cells. Rather, it is based on the equipment you are using to measure from the load cell instead. For example, the DAQ1500 has a 24 bit ADC on board. This means that the resolution of a load cell connected to it is 24 bits. Since the excitation voltage for the DAQ1500 is 5V, your expected resolution is:

This is affected by the chosen gain as well. In general, noise means you won't be able to achieve this reliably but the point is that resolution is not a useful spec for a load cell to have.

Safe Overload

The maximum axial load which can be applied without producing a permanent shift in performance characteristics beyond those specified.

Compensated Temperature

The range of temperature over which the load cell is compensated to maintain output and zero balance within specified limits.

Temperature Effect on Span

Span is also called rated output. This value is the change in output due to a 1-degree Celsius change in ambient temperature.

Temperature Effect on Zero

The change in zero balance due to a 1-degree Celsius change in ambient temperature.

Zero Balance

Zero Balance defines the maximum difference between the +/- output wires when no load is applied. Realistically, each sensor will be individually calibrated, at least for the output when no load is applied. Zero Balance is more of a concern if the load cell is being interfaced to an amplification circuit - the Phidget can easily handle enormous differences between +/-. If the difference is very large, the Phidget will not be able to use the higher Gain settings.