Selecting a Resistor for Your Power Guard

Introduction

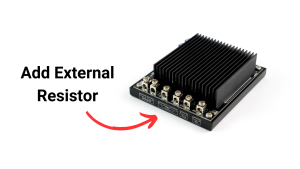

The 30V 50A Power Guard Phidget (SAF2020) is an easy-to-use device that protects your application from power surges caused by motors. For most applications, you can simply connect the power guard between your power supply and motor controller without any additional considerations.

In some cases, however, you will need to add an external power resistor. This guide will explain how to monitor your system, how to determine when an external resistor is necessary, and what resistor to choose.

System Monitoring

While you are developing your system, you may benefit from a better understanding of your supply voltage and current.

Voltage Monitoring

Some Phidget motor controllers offer built-in supply voltage sensing, these include:

If your controller does not offer built-in sensing, an external voltage sensor can be used. Simply wire the voltage sensor in parallel to your controller's power supply.

Example

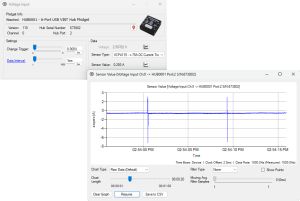

In this example, the supply voltage of a DCC1120 is monitored using the Phidget Control Panel for Windows.

When the motor rapidly changes direction, the supply voltage spikes which can be seen on the graph. When the voltage reaches the SAF2020's trip voltage the power guard steps in to dissipate the excess energy.

Current Monitoring

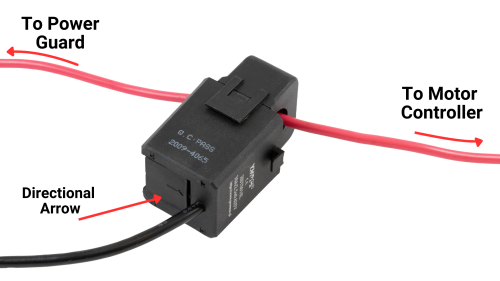

We recommend using a clip-on current transducer to monitor the current through your system. Simply clip the transducer onto the VDC wire between your power guard and your motor controller, and connect the other end to a VINT Hub Phidget using a Phidget cable.

Example

In this example, the supply current of a system with a DCC1120 is monitored using the Phidget Control Panel for Windows.

When the motor rapidly changes direction, the current begins sinking through the power guard which can be seen on the graph as a spike of negative current. Note: the directional arrow on your current transducer will determine positive or negative current in the Phidget Control Panel.

By monitoring your system's current during development, you can identify your worst-case regenerated current and plan accordingly.

Does My Application Require an External Resistor?

After monitoring your system, you may determine that an external resistor is required. Consider the following:

- If your supply voltage is above 36V for extended periods, this indicates that the power guard is unable to regulate the excess energy and your system would benefit from an external resistor.

- If your power guard is consistently sinking current, this indicates that the power guard is unable to regulate the excess energy and your system would benefit from an external resistor.

Without monitoring your system, these situations often indicate an external resistor is required:

- Excessive Heating. Power guards work by converting excess energy from power surges into heat. Because of this, some heating is expected. If your power guard is generating more heat than is acceptable for your design, consider adding an external resistor.

- Energy Dump Errors. The following Phidget motor controllers will throw an Energy Dump error:

- If you are using one of these controllers, and you are receiving an Energy Dump error, this is a clear indication that an external resistor is required for your application.

Purchasing an External Resistor

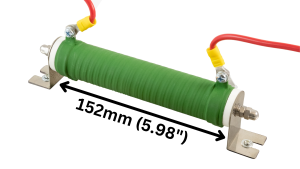

We recommend using a 0.5-ohm (~100W) chassis-mount wirewound power resistor.

During testing, we achieved excellent results with the TE80BR47J (pictured right). A physically larger resistor that is at least 6" is recommended.