|

Notice: This page contains information for the legacy Phidget21 Library. Phidget21 is out of support. Bugfixes may be considered on a case by case basis. Phidget21 does not support VINT Phidgets, or new USB Phidgets released after 2020. We maintain a selection of legacy devices for sale that are supported in Phidget21. We recommend that new projects be developed against the Phidget22 Library.

|

1129 User Guide: Difference between revisions

No edit summary |

|||

| (2 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

__NOINDEX__ | |||

[[Category:UserGuide]] | [[Category:UserGuide]] | ||

{{UserguideTOC|1129.jpg|1129}} | {{UserguideTOC|1129.jpg|1129}} | ||

| Line 62: | Line 63: | ||

==Technical Details== | ==Technical Details== | ||

The Touch Sensor changes value from 0 to 1000 (which corresponds to 0V - 5V) when it is touched. More specifically, this sensor is actually a capacitive change sensor. When the capacitance changes the sensor reports a thousand. If the sensor remains at 1000 for longer than 60 seconds, it will recalibrate back down to zero, regardless if the sensor is still being touched. This recalibration can also be done manually by unplugging and plugging the sensor back into the Interface kit. On the bottom side of the Touch Sensor there is a small exposed metallic pad. A soldered connection can be made to the pad to increase the size and dimensions of the touchable area, such as attaching the sensor to a metallic object or some wire. Once the sensor is recalibrated, the sensor’s value will increase to 1000 if the attached object is touched anywhere. Although there is an exposed metallic pad on the bottom of the board, the pad does not have to be touched directly to activate the sensor - touching anywhere on the board will activate the sensor. The sensor can work as a close | The Touch Sensor changes value from 0 to 1000 (which corresponds to 0V - 5V) when it is touched. More specifically, this sensor is actually a capacitive change sensor. When the capacitance changes the sensor reports a thousand. If the sensor remains at 1000 for longer than 60 seconds, it will recalibrate back down to zero, regardless if the sensor is still being touched. This recalibration can also be done manually by unplugging and plugging the sensor back into the Interface kit. This is a useful feature because it means that the sensor can be mounted on a flat surface such as a piece of glass or plastic and be reset so that it does not register the change in capacitance caused by the surface it is mounted on. On the bottom side of the Touch Sensor there is a small exposed metallic pad. A soldered connection can be made to the pad to increase the size and dimensions of the touchable area, such as attaching the sensor to a metallic object or some wire. Once the sensor is recalibrated, the sensor’s value will increase to 1000 if the attached object is touched anywhere. Although there is an exposed metallic pad on the bottom of the board, the pad does not have to be touched directly to activate the sensor - touching anywhere on the board will activate the sensor. The sensor can work as a close | ||

proximity sensor, sensing objects at a distance of up to 1/2” from the board in all directions without direct contact. The Touch sensor will also work through a thickness of up to 1/2” of glass, plastic, or paper. | proximity sensor, sensing objects at a distance of up to 1/2” from the board in all directions without direct contact. The Touch sensor will also work through a thickness of up to 1/2” of glass, plastic, or paper. | ||

| Line 79: | Line 80: | ||

==Product History== | ==Product History== | ||

{{UGhist}} | {{UGhist}} | ||

{{ | {{UGrow2|1129_0|November 2009 |0 |N/A |Product Release }} | ||

{{ | {{UGrow2|1129_1|September 2012 |1 |N/A |Redesign due to component obsolescence }} | ||

Latest revision as of 14:34, 9 May 2018

| |

| Go to this device's product page |

Getting Started

Checking the Contents

|

You should have received:

|

In order to test your new Phidget you will also need:

| |

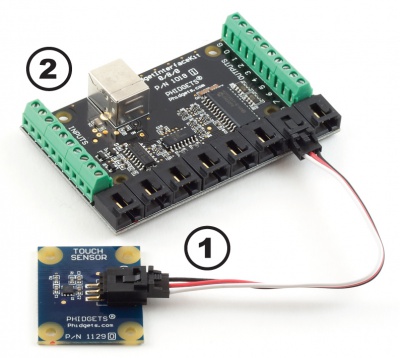

Connecting the Pieces

|

| |

Testing Using Windows 2000 / XP / Vista / 7

Make sure you have the current version of the Phidget library installed on your PC. If you don't, follow these steps:

- Go to the Quick Downloads section on the Windows page

- Download and run the Phidget21 Installer (32-bit, or 64-bit, depending on your system)

- You should see the

icon on the right hand corner of the Task Bar.

icon on the right hand corner of the Task Bar.

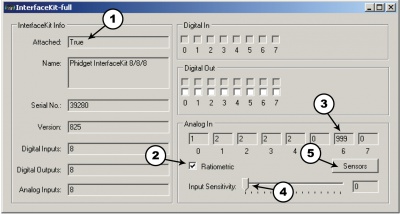

Running Phidgets Sample Program

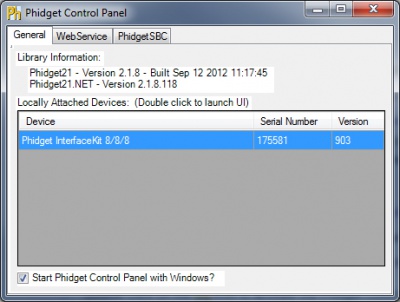

Double clicking on the ![]() icon loads the Phidget Control Panel; we will use this program to ensure that your new Phidget works properly.

icon loads the Phidget Control Panel; we will use this program to ensure that your new Phidget works properly.

The source code for the InterfaceKit-full sample program can be found in the quick downloads section on the C# Language Page. If you'd like to see examples in other languages, you can visit our Languages page.

Updating Device Firmware

If an entry in this list is red, it means the firmware for that device is out of date. Double click on the entry to be given the option of updating the firmware. If you choose not to update the firmware, you can still run the example for that device after refusing.

|

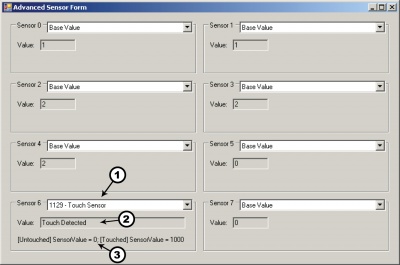

Double Click on the |

| |

|

| |

|

|

Testing Using Mac OS X

- Go to the Quick Downloads section on the Mac OS X page

- Download and run the Phidget OS X Installer

- Click on System Preferences >> Phidgets (under Other) to activate the Preference Pane

- Make sure that the is properly attached.

- Double Click on in the Phidget Preference Pane to bring up the Sample program. This program will function in a similar way as the Windows version.

Using Linux

For a step-by-step guide on getting Phidgets running on Linux, check the Linux page.

Using Windows Mobile / CE 5.0 / CE 6.0

For a step-by-step guide on getting Phidgets running on Windows CE, check the Windows CE page.

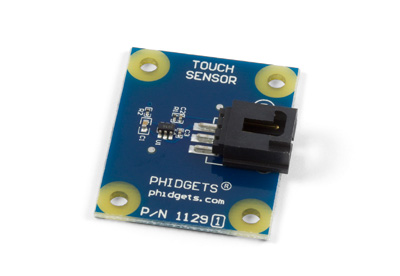

Technical Details

The Touch Sensor changes value from 0 to 1000 (which corresponds to 0V - 5V) when it is touched. More specifically, this sensor is actually a capacitive change sensor. When the capacitance changes the sensor reports a thousand. If the sensor remains at 1000 for longer than 60 seconds, it will recalibrate back down to zero, regardless if the sensor is still being touched. This recalibration can also be done manually by unplugging and plugging the sensor back into the Interface kit. This is a useful feature because it means that the sensor can be mounted on a flat surface such as a piece of glass or plastic and be reset so that it does not register the change in capacitance caused by the surface it is mounted on. On the bottom side of the Touch Sensor there is a small exposed metallic pad. A soldered connection can be made to the pad to increase the size and dimensions of the touchable area, such as attaching the sensor to a metallic object or some wire. Once the sensor is recalibrated, the sensor’s value will increase to 1000 if the attached object is touched anywhere. Although there is an exposed metallic pad on the bottom of the board, the pad does not have to be touched directly to activate the sensor - touching anywhere on the board will activate the sensor. The sensor can work as a close proximity sensor, sensing objects at a distance of up to 1/2” from the board in all directions without direct contact. The Touch sensor will also work through a thickness of up to 1/2” of glass, plastic, or paper.

Customizing Sensitivity

The capacitor labelled C1 is the "sensing" capacitor. In other words this is the capacitor that determines how sensitive the sensor is. By default it is a 10nF capacitor. By changing this value we can adjust the sensitivity. Smaller capacitors will yield lower sensitivity while higher values will yield higher sensitivity. The IC (integrated circuit) on the 1129 specifies that the acceptable range for C1 is 2-50nF. In testing, 2nF will not sense through any thickness of material while 50nF can sense through over 1" of material and even through double paned windows with an air gap of up to 3/4". If the size of your capacitive touch surface is very large, you may have to increase C1 even more. Up to 100nF even. (Note: C1 is soldered onto the board, in order to replace it you will need a soldering iron).

Other Interfacing Alternatives

If you want maximum accuracy, you can use the RawSensorValue property from the PhidgetInterfaceKit. To adjust a formula, substitute (SensorValue) with (RawSensorValue / 4.095) If the sensor is being interfaced to your own Analog to Digital Converter and not a Phidget device, our formulas can be modified by replacing (SensorValue) with (Vin * 200). It is important to consider the voltage reference and input voltage range of your ADC for full accuracy and range.

|

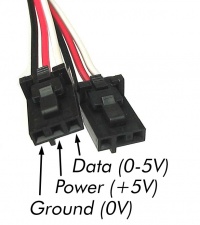

Each Analog Input uses a 3-pin, 0.100 inch pitch locking connector. Pictured here is a plug with the connections labelled. The connectors are commonly available - refer to the Analog Input Primer for manufacturer part numbers. |

| |

API

Phidget analog sensors do not have their own API- they simply output a voltage that is converted to a digital value and accessed through the "Sensor" properties and events on the PhidgetInterfaceKit API. It is not possible to programmatically identify which sensor is attached to the Analog Input. To an InterfaceKit, every sensor looks the same. Your application will need to apply formulas from this manual to the SensorValue (an integer that ranges from 0 to 1000) to convert it into the units of the quantity being measured. For example, this is how you would use a temperature sensor in a C# program:

// set up the interfacekit object

InterfaceKit IFK = new InterfaceKit();

// link the new interfacekit object to the connected board

IFK.open("localhost", 5001);

// Get sensorvalue from analog input zero

int sensorvalue = IFK.sensors[0].Value;

// Convert sensorvalue into temperature in degrees Celsius

double roomtemp = Math.Round(((sensorvalue * 0.22222) - 61.11), 1);

See the PhidgetInterfaceKit User Guide for more information on the API and a description of our architecture.

For more code samples, find your preferred language on the Languages page.

Product History

| Date | Board Revision | Device Version | Comment |

|---|---|---|---|

| November 2009 | 0 | N/A | Product Release |

| September 2012 | 1 | N/A | Redesign due to component obsolescence |