This NEMA-34 motor generates 34 kg-cm of holding torque at 2.8 Amps. It comes with the rear shaft exposed, so you can mount an encoder or shaft coupler.

Note: Connecting the motor directly to a power supply will destroy the motor and void the warranty. It must be used with a constant current / chopper drive controller such as a Phidget stepper controller.

This motor is large enough that the back EMF generated from stalling or changing directions could easily damage your motor controller. If you're planning on using this motor in high-speed or high-torque applications, feel free to contact us for advice.

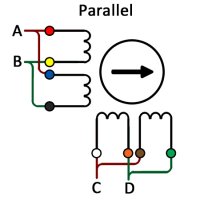

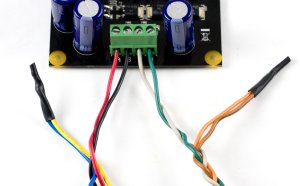

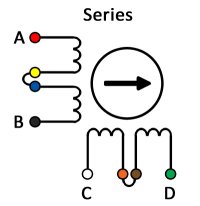

This motor must be controlled by a stepper motor controller. These diagrams show to wiring configurations: series and parallel. Series wiring will result in higher torque when the motor is stopped or at low speeds. Parallel wiring will provide better torque at higher speeds, but less torque overall. Since the current in parallel mode is split between two paths, the current rating is doubled. When connecting motor wires to one another, you must solder or screw clamp them together rather than just twisting them together.

Note: Make sure to unplug the power cord from the motor controller before switching wires around.

| Parallel Wiring | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|||||||||||||||||||||||||

| Series Wiring | |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|||||||||||||||||||||||||||||||||||

The following stepper controllers can be used to drive this motor:

| Product | Controller Properties | Electrical Properties | |||

|---|---|---|---|---|---|

| Part Number | Price | Motor Position Resolution | Stepper Velocity Resolution | Stepper Velocity Max | Available Current per Coil Max |

4A Stepper Phidget

|

$50.00 | 1⁄16 Step (40-Bit Signed) | 1 1⁄16 steps/sec | 115000 1⁄16 steps/sec | 4 A |

8A Stepper Phidget

|

$80.00 | 1⁄16 Step (40-Bit Signed) | 1 1⁄16 steps/sec | 115000 1⁄16 steps/sec | 8 A |

PhidgetStepper Bipolar HC

|

$90.00 | 1⁄16 Step (40-Bit Signed) | 1 1⁄16 steps/sec | 250000 1⁄16 steps/sec | 4 A |

The rear shaft of this motor can be equipped with an encoder for applications where you need to keep track of the exact position, velocity, or acceleration of the motor. The mounting holes on the back of this motor are compatible with the following encoders:

| Product | Encoder Properties | |||

|---|---|---|---|---|

| Part Number | Price | Output Circuit Type | Encoder Resolution | Encoder Speed Max |

Rotary Encoder - For 4mm Motor Shaft 300 CPR

|

$25.00 | Push-Pull | 300 CPR | 6000 RPM |

Rotary Encoder - For 4mm Motor Shaft 40 CPR

|

$10.00 | Push-Pull | 40 CPR | 6000 RPM |

If you need to connect the main shaft of this motor to the shaft of another device, you can use a shaft coupler:

| Product | Physical Properties | |||||

|---|---|---|---|---|---|---|

| Part Number | Price | Inner Diameter | Material | Coupling Rated Torque | Coupling Rated Speed | Torsional Stiffness |

Jaw Coupling Half 12mm Series 12

|

$3.60 | 12 mm | Aluminum | 35.7 kg·cm | 12000 RPM | — |

Jaw Coupling Half 12mm Series 24

|

$6.85 | 12 mm | Aluminum | 611.8 kg·cm | 4000 RPM | — |

If you're using this motor to drive a rotary system that requires a lot of torque, you may be interested in pulleys and sprockets. By using a two pulleys or sprockets of different sizes, you can increase the gear ratio of the motor. Pulleys and sprockets can also be used to transmit the motor's rotation over a long distance. For more guidance on building a transmission system, visit our Rotary Motion Guide. Here is a list of our 12mm bore pulleys and sprockets:

| Product | Physical Properties | ||

|---|---|---|---|

| Part Number | Price | Inner Diameter | Number of Teeth |

#25 Chain Sprocket with 12mm Bore and 12 Teeth

|

$3.25 | 12 mm | 12 |

#25 Chain Sprocket with 12mm Bore and 18 Teeth

|

$3.75 | 12 mm | 18 |

#25 Chain Sprocket with 12mm Bore and 32 Teeth

|

$5.00 | 12 mm | 32 |

#25 Chain Sprocket with 12mm Bore and 52 Teeth

|

$8.00 | 12 mm | 52 |

GT2 Pulley with 12mm Bore and 36 Teeth

|

$3.00 | 12 mm | 36 |

GT2 Pulley with 12mm Bore and 44 Teeth

|

$3.00 | 12 mm | 44 |

GT2 Pulley with 12mm Bore and 60 Teeth

|

$3.55 | 12 mm | 60 |

GT2 Pulley with 12mm Bore and 80 Teeth

|

$4.45 | 12 mm | 80 |

#40 Chain Sprocket with 12mm Bore and 9 Teeth

|

$4.25 | 12 mm | 9 |

#40 Chain Sprocket with 12mm Bore and 14 Teeth

|

$4.50 | 12 mm | 14 |

#40 Chain Sprocket with 12mm Bore and 20 Teeth

|

$7.00 | 12 mm | 20 |

GT5 Pulley with 12mm Bore and 16 Teeth

|

$3.50 | 12 mm | 16 |

GT5 Pulley with 12mm Bore and 24 Teeth

|

$4.00 | 12 mm | 24 |

GT5 Pulley with 12mm Bore and 34 Teeth

|

$5.00 | 12 mm | 34 |

GT5 Pulley with 12mm Bore and 50 Teeth

|

$7.40 | 12 mm | 50 |

GT5 Pulley with 12mm Bore and 72 Teeth

|

$12.95 | 12 mm | 72 |

Systems with heavy loads or pulley/sprocket assemblies often put a lot of sideways strain on the motor shaft. If you're using this motor to drive such a system, you can use rotary bearings to protect the motor:

| Product | Physical Properties | Mechanical Properties | |||

|---|---|---|---|---|---|

| Part Number | Price | Inner Diameter | Bearing Type | Static Load | Dynamic Load |

Flanged Rotary Bearing for 12mm Shaft

|

$4.00 | 12 mm | Rotary Shaft (Flanged) | 2.4 kN | 5.1 kN |

Pillow Block Rotary Bearing for 12mm Shaft

|

$4.00 | 12 mm | Rotary Shaft (Pillow Block) | 2.4 kN | 5.1 kN |

| Motor Properties | |

|---|---|

| Motor Type | Bipolar Stepper |

| Manufacturer Part Number | 86STH65-2808B |

| Step Angle | 1.8° |

| Step Accuracy | ± 5 % |

| Holding Torque | 34 kg·cm |

| Rated Torque | 30 kg·cm |

| Maximum Motor Speed | 200 RPM |

| Electrical Properties | |

| Recommended Voltage | 30 V DC |

| Coil Resistance | 1.4 Ω |

| Rated Current (Series Wiring) | 2 A |

| Rated Current (Parallel Wiring) | 4 A |

| Phase Inductance | 3.9 mH |

| Physical Properties | |

| Shaft Diameter | 12 mm |

| Rear Shaft Diameter | 3.9 mm |

| Mounting Plate Size | NEMA - 34 |

| Weight | 1.8 kg |

| Number of Leads | 8 |

| Wire Length | 400 mm |

| Customs Information | |

| Canadian HS Export Code | 8501.31.00 |

| American HTS Import Code | 8501.31.20.00 |

| Country of Origin | CN (China) |

| Product | Motor Properties | Electrical Properties | Physical Properties | Gearbox Properties | ||||

|---|---|---|---|---|---|---|---|---|

| Part Number | Price | Step Angle | Rated Torque | Maximum Motor Speed | Recommended Voltage | Shaft Diameter | Weight | Gear Ratio |

NEMA11 - 1.8 Degree - 0.67A Stepper - Gearless

|

$16.00 | 1.8° | 520 g·cm | 1300 RPM | 24 V DC | 5 mm | 111.4 g | — |

NEMA11 - 1.8 Degree - 1.5A Stepper - 27:1 Gearbox

|

$38.00 | 1.8° | 14 kg·cm | 50 RPM | 24 V DC | 6 mm | 217.5 g | 26 103⁄121 : 1 |

NEMA11 - 1.8 Degree - 0.67A Stepper - 100:1 Gearbox

|

$38.00 | 1.8° | 32 kg·cm | 13 RPM | 24 V DC | 6 mm | 243.6 g | 99 1044⁄2057 : 1 |

NEMA14 - 1.8 Degree - 1A Stepper - Gearless

|

$16.00 | 1.8° | 1.2 kg·cm | 1000 RPM | 24 V DC | 5 mm | 200 g | — |

NEMA17 - 0.9 Degree - 1.68A Stepper - Gearless

|

$20.00 | 0.9° | 3.3 kg·cm | 400 RPM | 24 V DC | 5 mm | 288 g | — |

NEMA17 - 1.8 Degree - 1.68A Stepper - Gearless

|

$16.00 | 1.8° | 3.3 kg·cm | 1000 RPM | 24 V DC | 5 mm | 289 g | — |

NEMA17 - 1.8 Degree - 1.68A Stepper - 5.18:1 Gearbox

|

$40.00 | 1.8° | 18 kg·cm | 200 RPM | 24 V DC | 8 mm | 457 g | 5 2⁄11 : 1 |

NEMA17 - 1.8 Degree - 1.68A Stepper - 14:1 Gearbox

|

$42.00 | 1.8° | 30 kg·cm | 70 RPM | 24 V DC | 8 mm | 502 g | 13 212⁄289 : 1 |

NEMA17 - 1.8 Degree - 1.68A Stepper - 27:1 Gearbox

|

$44.00 | 1.8° | 30 kg·cm | 40 RPM | 24 V DC | 8 mm | 503 g | 26 103⁄121 : 1 |

NEMA17 - 1.8 Degree - 1.68A Stepper - 51:1 Gearbox

|

$46.00 | 1.8° | 48 kg·cm | 20 RPM | 24 V DC | 8 mm | 564 g | 50 4397⁄4913 : 1 |

NEMA17 - 1.8 Degree - 1.68A Stepper - 100:1 Gearbox

|

$48.00 | 1.8° | 48 kg·cm | 10 RPM | 24 V DC | 8 mm | 564 g | 99 1044⁄2057 : 1 |

NEMA23 - 0.9 Degree - 2.8A Stepper - Gearless

|

$28.00 | 0.9° | 11.2 kg·cm | 500 RPM | 24 V DC | 1⁄4″ | 695 g | — |

NEMA23 - 1.8 Degree - 2.8A Stepper - 4.25:1 Gearbox

|

$70.00 | 1.8° | 46.6 kg·cm | 165 RPM | 24 V DC | 12 mm | 1.2 kg | 4 1⁄4 : 1 |

NEMA23 - 1.8 Degree - 2.8A Stepper - 15:1 Gearbox

|

$72.00 | 1.8° | 150 kg·cm | 50 RPM | 24 V DC | 12 mm | 1.3 kg | 15 3⁄10 : 1 |

NEMA23 - 1.8 Degree - 2.8A Stepper - 77:1 Gearbox

|

$74.00 | 1.8° | 240 kg·cm | 10 RPM | 24 V DC | 12 mm | 1.5 kg | 76 49⁄64 : 1 |

NEMA34 - 1.8 Degree - 4A Stepper - Gearless

|

$60.00 | 1.8° | 30 kg·cm | 200 RPM | 30 V DC | 12 mm | 1.8 kg | — |